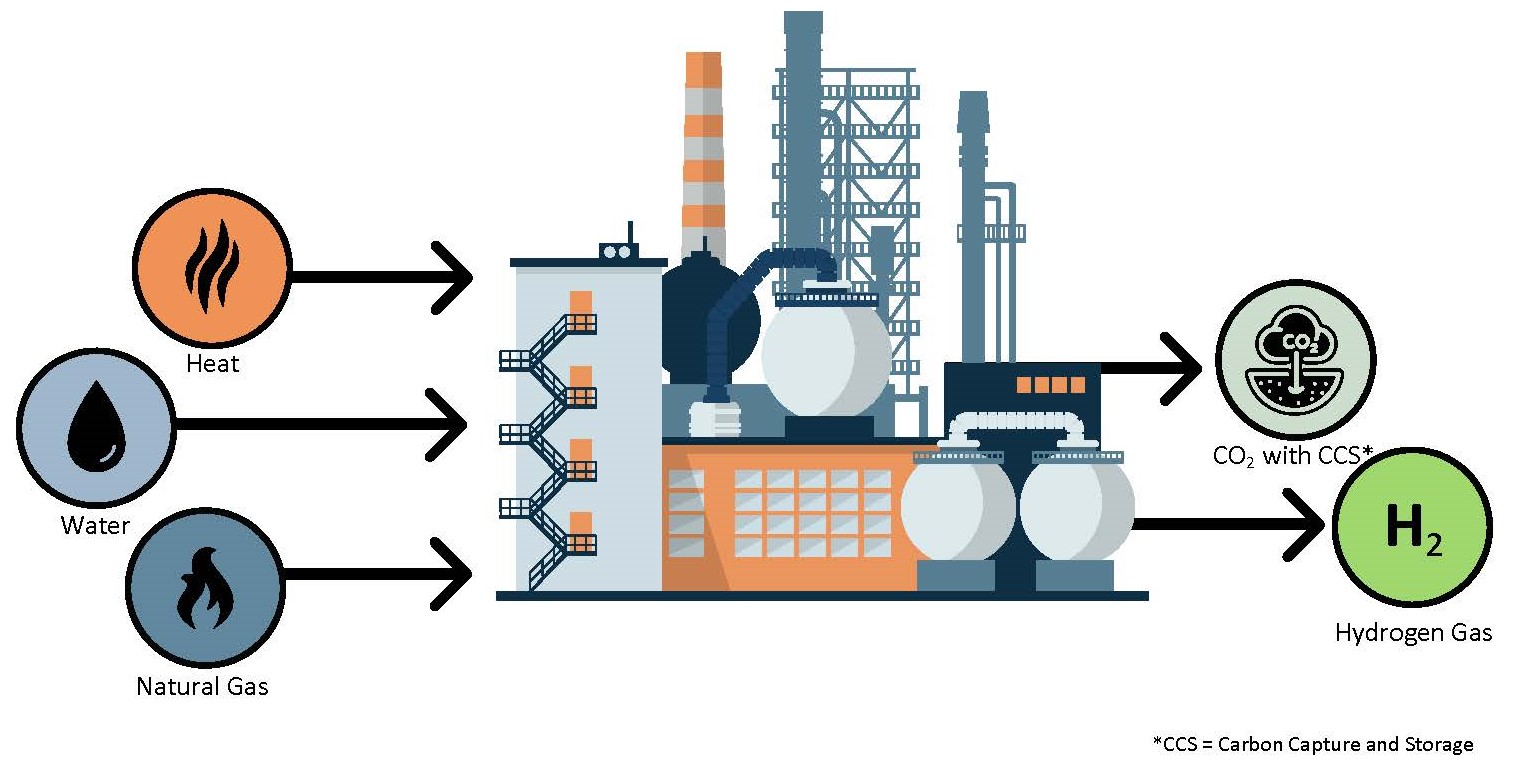

In the world of hydrogen production and Carbon Capture Utilization and Storage (CCUS), control valves are the unsung heroes. Just like the ARCH2 Hub’s ambitious project (which features capturing CO2 subsurface), every CO2 capture system needs valves that don’t just perform—they excel. After all, what’s the point of capturing CO2 if it leaks out through your valves?

When it comes to control valves, service, reliability, and efficiency are non-negotiable. But there’s another critical factor: keeping the CO2 securely contained. Leaky valves can turn your best CCUS efforts into a CO2 escape route.

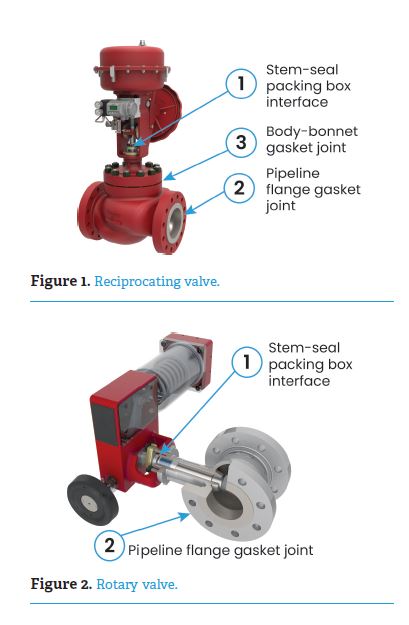

For those in the know—users, project developers, and engineers—being aware of potential fugitive emissions like CO2 is crucial. Reciprocating globe control valves can be equipped with “packing” around potential leak points such as the stem, which helps minimize emissions. However, if you want to avoid most emissions altogether, alternative technologies, such as rotary globe control valves, are worth considering.

For instance, the Baker Hughes Masoneilan Camflex 35002 is designed to completely eliminate body-to-bonnet leakage. With an enclosed stem and fewer leak points compared to traditional reciprocating globe valves, the Camflex valve helps ensure that your CO2 stays put, making your CCUS project both smarter and greener.

As hydrogen production and CCUS applications expand, remember: it’s not just about capturing CO2—it’s about keeping it captured. Selecting the right valve technology can make all the difference.